Minocar™ 4.0

Next Generation

Innovation and experience at the service

of

the corrugated cardboard industry.

Discover the Coromat system with Minocar™

At the beginning of the 1990s, Cerestar (now Cargill) developed a new global preparation process based on native starches. This process was called Minocar™. To offer a service to its customers, Cerestar developed a system called Coromat, in which it brought together all the known starch glue preparation methods, with Minocar™ being the most evolved method in the world.

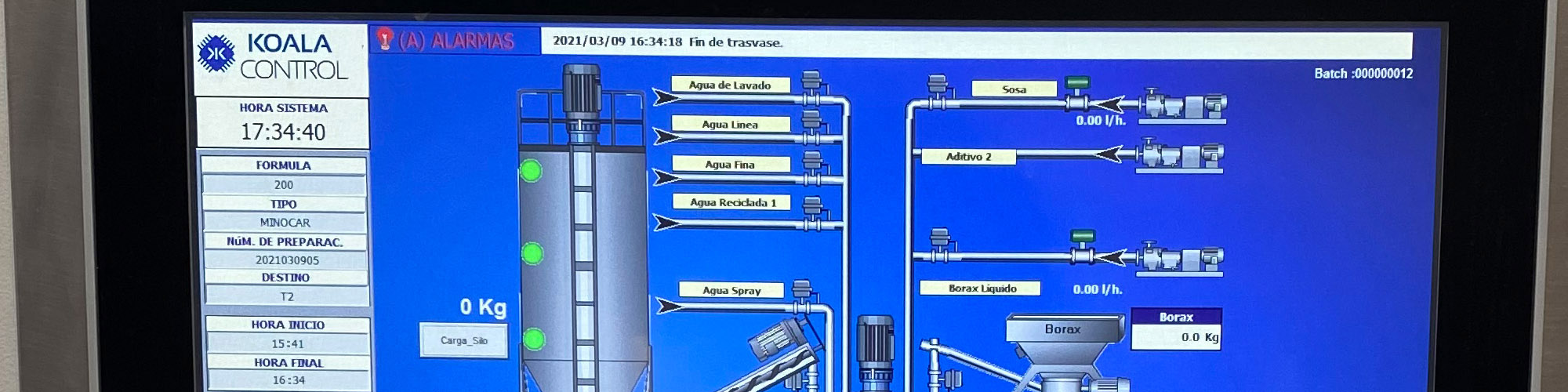

The team at Koala Control took over in 1996 and started the development of these glue production systems at a European level, becoming the European standard and only solution for all the systems that Cargill supplies, in 2000.

Multi-process system designed to work in Minocar™, Stein Hall, OBM and Non-carrier.

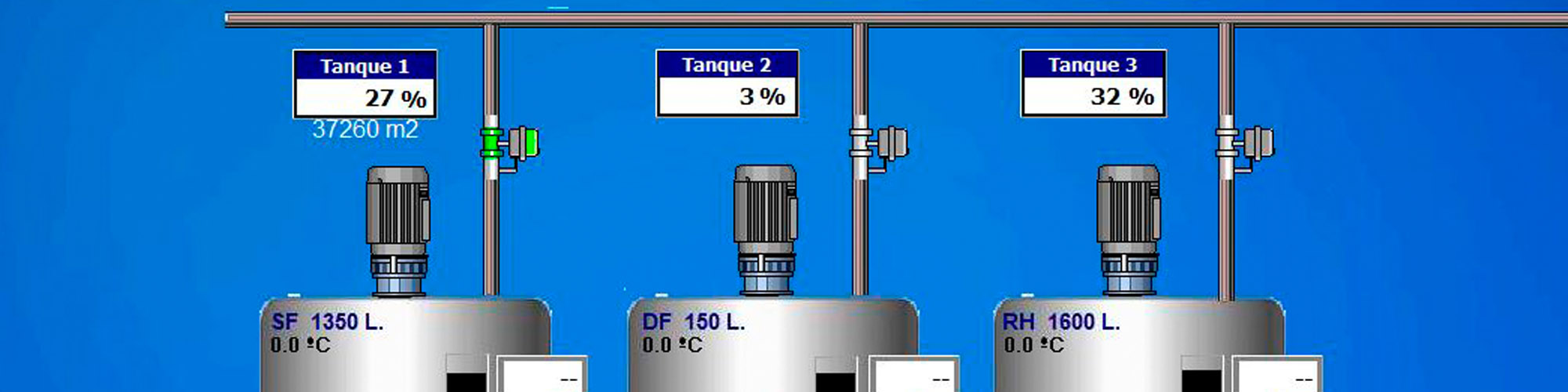

Coromat is the European benchmark as, for the first time, a single piece of equipment provided the end client with three glue preparation methods in a single system. The Coromat system allows glues to be manufactured in Minocar, Stein Hall, OBM and Non-carrier. At Koala Control, we offer the best system on the market, permanently updated, to always get the best performance.

Current starch glue preparation methods.

To prepare glue, the main raw material is starch. Its origin can be various cereals: wheat, corn, tapioca, potato, etc. Inside this raw material, there are native starches, modified starches or pregelatinised starches. Each of them must be processed using the most suitable method to prepare glue. At Koala Control, we provided the technology to process using the method that best suits your needs.

Stein-Hall

This was the first glue preparation method based on cereal by-products developed in 1935 by Stein Hall & Co. The preparation method is based on two phases: a small primary phase and a secondary greater one. The result is a starch glue with a Newtonian/dilatant rheology.

OBM (One bag mix)

This is a product supplied by starch producing companies which only requires an excellent control of shear stress in agitation to obtain the final desired viscosity.

Non-carrier

Unlike the Stein Hall and Minocar™ processes, that were developed by means of the primary phase and a secondary one, the Non-carrier is developed in a single phase, obtaining glue performance equivalent to Minocar™.

Minocar™

Developed by the Cerestar Group (now Cargill) in the 1990s to increase the performance of native starch glue under any condition and operations. A system based on two phases. It offers a pseudoplastic/thixotropic rheology.

Endless innovation with Minocar™ 4.0 Next Generation

Since 1996, Koala Control has been developing and evolving this glue preparation method which is currently at the Minocar™ Next Generation level. Unlike other systems, our system has the advantages of years of research and experience in the sector.

The molecular development of starch in an environment of different kinds of water, different temperature and different caustic sensitivity can affect the final quality of the product and its repeatability. Our algorithms, based on artificial intelligence, provide more than 30 years' learning interpreting the information about the process in real time. With our technology and development, we can maintain high gluing performance at all times and under any conditions.

Ecology upfront

Our system can use reused water to prepare the glues maintaining the quality of the end glue. Whether these waters are from cleaning the machine or even water from ink purification. Our commitment to clients who value the environment has led us to develop the best solutions for treating wastewater and reusing it with 100% effectiveness in glue production. At Koala Control, we use unique solutions to recover wastewater.

Contact us now

Our commercial team will contact you to develop the best solution.